- Visit our Location:

Larecoweg no.28 – km 37 ½, Saramacca, Suriname S.A.

We will be glad to assist you

Larecoweg no.28 – km 37 ½, Saramacca, Suriname S.A.

We will be glad to assist you

Give us a call

Give us a call

In this context, we have prepared and deployed a Safety Management Plan, covering all safety aspects based on mandatory safety requirements after analyzing safety risks at our processes and lessons learned from each project. This plan is being evaluated in the

1st month of each year, and if deemed necessary revised with lessons learned from the past year and focus, amongst others, of the following aspects:

Priorities at STP are #1 Safety #2 Our People #3 Quality

All STP workers are encouraged to identify safety risk and unsafe work practices. Every worker has the authority to stop their own work or the work of others, if they see unsafe work practices.

All STP field workers are safety trained and empowered before working on the job site. All Project Manager and Supervisors must conduct safety toolbox meetings every day prior to start the works focusing on, amongst others, (potential) safety risks identified the day before and mitigation measures.

Every crew must start the day by actively participating in a Job Hazard Analysis or “JSA”. It has been proven that thinking through the steps of your task and identifying possible safety hazards result in fewer incidents.

During our project planning process STP’s management review and assess every project to determine any special safety consideration. STP place full time safety personnel on a project if the job site is congested or the schedule is accelerated. STP also opt to prefabricate in its shop to reduce risk.

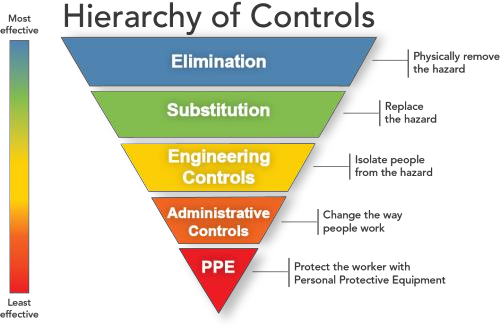

On the rare occasions we have an incident or near miss at STP our HSE Controller may, in consultation with the Managing Director, stop the works, perform a thorough investigation and determine the cause of incident. The Managing Director reviews the findings and corrective action with the Project Managers and Supervisors and ensure they understand what steps can be taken to eliminate or reduce this hazard in the future.

To ensure that our workers are safe during performance of their duties, we have assessed all working facilities to identify potential risks. Based on the risk assessment we provide our workers with the best possible PPE to perform the duties safely making sure that they can safely back to their families.

Beyond the PPE’s, based on the assessment specific safety signs are placed in all working sites indicating the mandatory PPE’s necessary to enter these sites, and all necessary equipment, such as Fire extinguishers and First-aid kits are readily available if and when needed.

Weekly safety talks with the whole team are an integral part of the companies’ communication structure. Safety talks are being held every Monday with the whole team to evaluate and to emphasize STP’s safety policies and procedures and to present potential safety risks based on benchmarking or desktop research for the awareness of our team. Moreover, all potential hazards mentioned by our workers in these meetings are investigated by our HSE team and where necessary actions are being undertaken to further improve the safety our workers and to satisfy their safety feelings.

Therefore, it is our goal and driving ambition to be the premier partner of choice for our Customers by delivering reliable, complete construction solutions that create value for our Customers, by sustainably and passionately leveraging new technologies and operating expertise and experience.

To meet this goal, we have defined an extensive Quality Management System (QMS) meant to document important policies, processes and procedures and facilitate the implementation of these procedures to achieve high-quality outputs that align with our company’s goals and objectives.

With our QMS we coordinate and direct the activities of our business processes in order to achieve maximum customer satisfaction and meet international requirements, to enhance efficiency on our side and work towards continual improvement.

In the context of continual improvement, we continuously evaluate the developments at our customers and suppliers on the local supplier’s market to identify rooms for improvement. We do not hesitate to invest in resources, systems, expertise or equipment to meet our customers’ needs and to maintain or even improve our competitive power. We consider ourselves a strong dynamic and forward think company ready to accept any business challenge on a professional manner and on mutual respect.